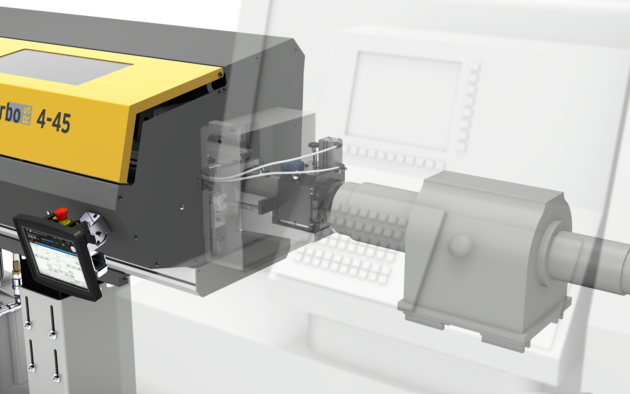

turbo RS 4-45

The bar feeder for bar diameters of 4 - 45 mm.

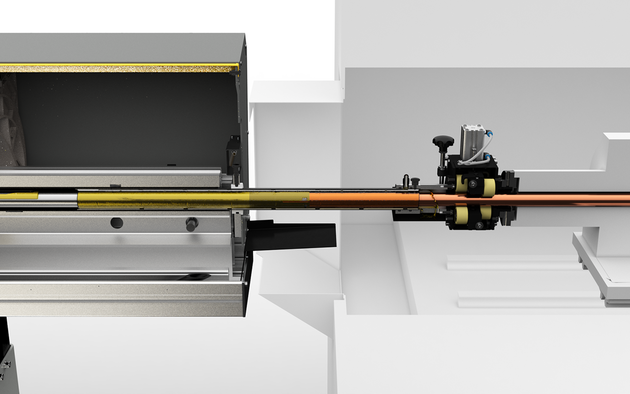

The turbo RS 4-45 guides material bars seemlessly right up to the lathe‘s spindle with a movable guide module. The bar feeder operates on the two-step feed principle, known from the turbo-series. By pivoting the pusher, this allows for a very compact and thus space-saving design.

Area of application:

Sliding headstock lathes with up to 38 mm nominal throughput gap, which process small and medium-sized diameter ranges.

Where lathes are used for material bars with frequently differing diameters, the turbo RS 4-45 V variant model provides an optimum solution for further production efficiency increases.

The V variant has moveable guiding segments that are automatically set to the required material bar diameter, thus preventing the need for refitting the guide channel inserts or changing the pusher over wide ranges. The proven benefits of the hydrodynamic bearing effect of the oil-flushed channel are not affected. After inputting the material bar diameter on the control panel, the guiding segments in the channel set themselves and the stops of the material bar separation system are automatically moved to the required position.

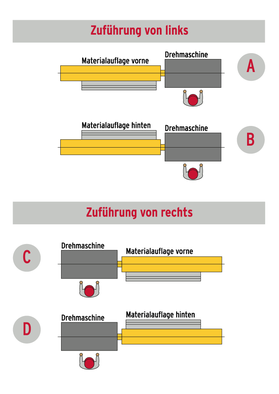

Available installation situations

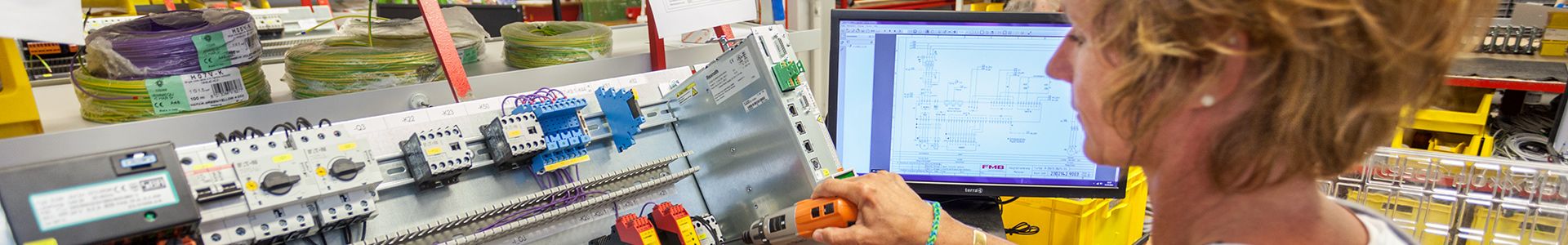

Simple and convenient - the ERGOlogic control ...

Portable control panel

Modern touch control with generously sized 8.4“ screen makes an intuitive operating concept

possible for a faster learning phase. Integrated assistant function for guided set up for inexperienced users.

Efficient, practical handling...

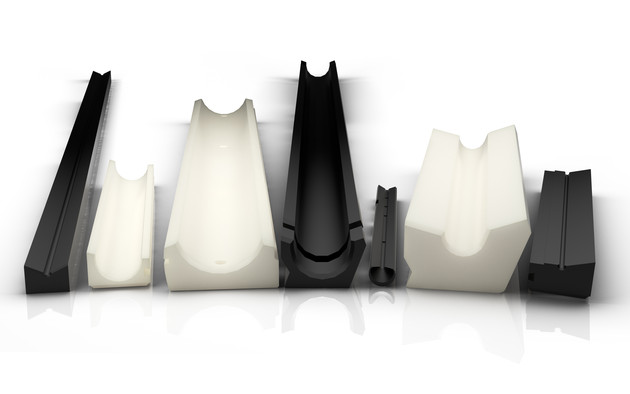

Guide channel inserts

The guide channel inserts are quick easy to replace so that the channel diameter can be adapted to the optimum diameter range of the material bars to be processed.

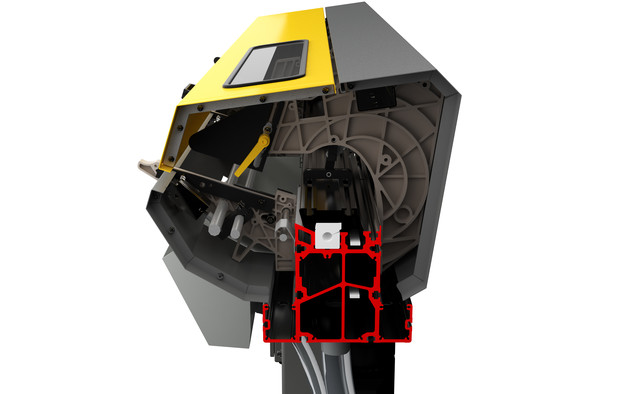

Stable design...

Machine support

The torsion-resistant machine support of extruded aluminium forms the solid basis for the loading magazine. It also holds the diameter-related inserts for the guide channel.

Stable design...

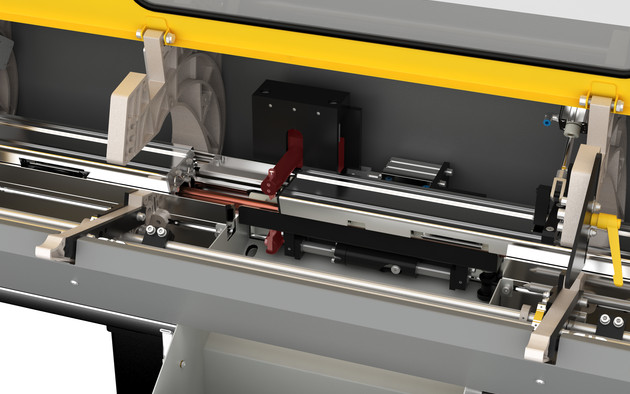

Material bar grippers

The stable gripper design guarantees secure drawing in of the material bar and removal of the remnant piece.

Spindle liners

Spindle liners

On request FMB can also supply spindle liners to match a substantial number of lathe types; these enable the spindle opening to be optimally adapted to match the guide channel diameter.

oil-flooded guide channel

The continuously oil-flooded guide channel guarantees the highest level of guide properties seamlessly right up to the spindle.