vario E

Standard unloading solutions

With the vario E, FMB offers a solution for the automated transfer of workpieces after the machining process in the lathe through the sub-spindle. The lateral material storage for storing the finished parts can be adapted to suit the works’ individual requirements from the addition of depositing tables through to timed cycle belts. Unloading is by means of an unloading bar with gripper which moves counter to the direction of travel to pick up the workpiece.

The gripper can be designed in various different ways depending on the part geometry and customer requirements. The workpiece is removed via a guide channel and transferred to the material storage, after being automatically ejected from a clamping sleeve, e.g. by means of a ram integrated in the unloading bar.

You can find more details here about customer-specific individual applications.

Features

- Design as a modular system for flexible adaptation to the relevant lathe type and implementation of customer-specific special solutions

- Possibility of installing a chip conveyor beneath the unload system

Different gripper concepts possible:

- Unloading bar with spring gripper, clamping sleeve or clamping mandrel

- Unloading bar with pneumatic gripper

- Unloading tube

Various storage options available:

- Depositing table, adjustable angle of inclination

- Cycle belt

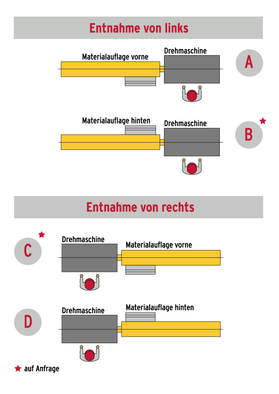

Available installation situations