SL 80 V

Short loader for the processing of round and profile materials up to 80 mm bar diameter

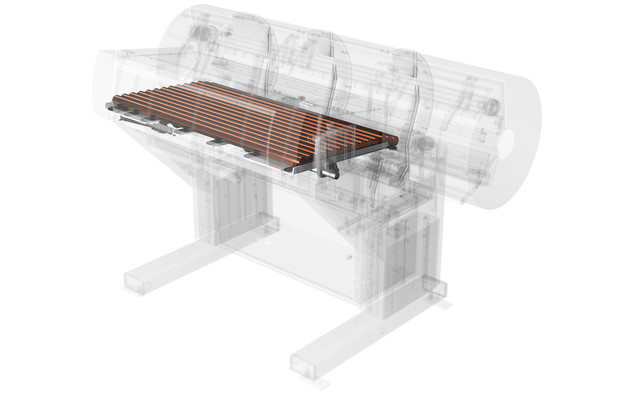

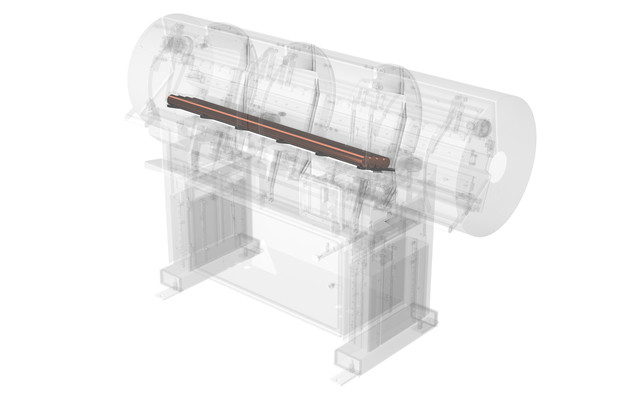

The FMB SL 80 V is a short bar loader that has been designed for the flexible processing of round material and a wide range of different profile materials in bar lengths between 1,100 and 1,400 mm. The maximum material bar length always depends on the spindle length of the lathe. The material bar is fed to the main spindle from the short loader by the feed system.

During processing the material bar does not come into contact with the loading magazine. In order to ensure optimum vibration-free guidance of the bar, it is necessary to insert spindle liners to match the diameter.

The SL series has an impressive modern design and many innovative detailed solutions in order to offer the optimum solution for a wide range of different requirements related to bar section feed. It has a modular design, with differences including the pusher bar lengths available and the supply options for material bars.

Area of application:

Single-spindle lathes up to approx. 80 mm nominal throughput, on which bar material cut to the length of the spindle is machined.

Characteristics

- Modern functional design with a good view of the processes in progress

- Variable “V-Channel” as bar guide with fully automatic adaptation to the diameter or the profile shape

- Small footprint thanks to integrated longitudinal displacement system

- Choice of different material storage modules

Modular design...

Storage system “Ramp”

- Flexible and process-reliable, independent of bar diameter

- Generously dimensioned lateral material storage

- Angle of inclination infinitely adjustable

Modular design...

Storage system “Compact”

- Ideal for the production of very small series with frequently changing material diameters or profile shapes

- Short lateral material storage for storing individual bars

- Compact design with small space requirement

Modular design...

Storage system “Lift”

- Ergonomic loading, particularly where heavier bar material with a diameter > 50 mm is often processed

- Loading height remains in the range of approx. 500 to 700 mm independently of the centre axis height of the lathe

- Generously dimensioned material storage with angle adjustment

- Optional loading of bars in the smaller diameter range directly onto the upper material storage also without Lift

Available loading options

Practical operation and handling...

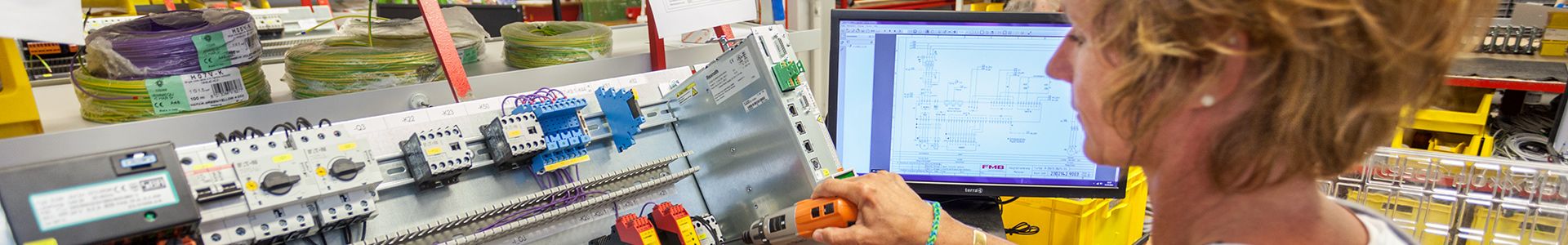

Always on hand - mobile control panel

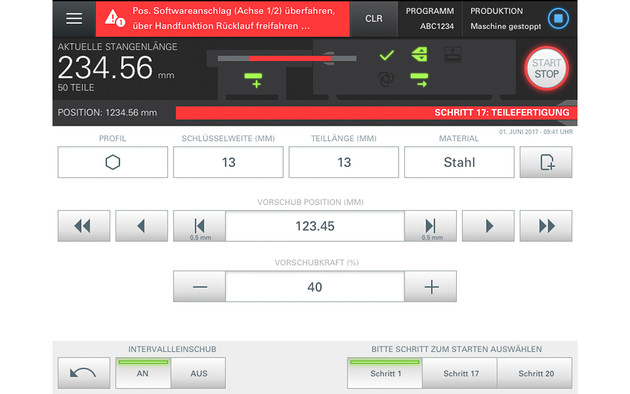

- Simple and convenient operation – the ERGOlogic control from FMB

- Modern touch operation with generously sized 8.4" screen

- Ergonomically designed shape with integrated magnetic holders for flexible attachment in the operator’s working environment

Practical operation and handling...

Modern user guidance - touch operation

- Intuitive operating concept for a faster user learning phase

- Assistant functions for guided set-up for inexperienced operators

- Selection of different user roles to specify access rights to defined functions and setting values

- Comprehensive storage options for order-related parameter sets for the fast set-up of repeat production orders

Variable and fully automatic...

Efficient feeding – “V-Channel”

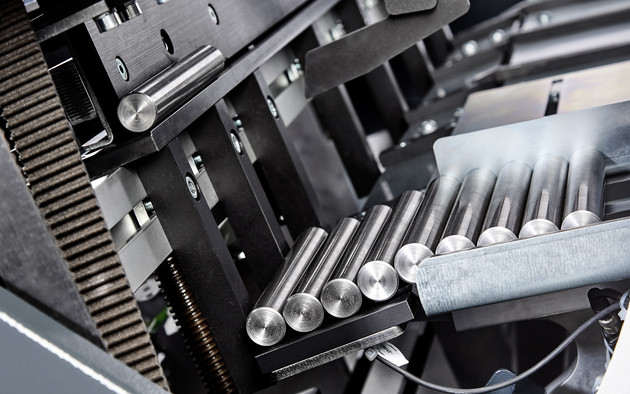

- Servo-electric adjustment of the “V-Channel geometry” for automatic adaptation to the diameter or profile shape selected

- Continuous “V-Channel” for the efficient feeding of short bar sections

- Free choice of bar centre, also for off-centre feeding and for the precise angular feeding of profile material

Variable and fully automatic...

Flexible use – free choice of profiles

- Innovative separation and guide system for the flexible processing of all common types of material as well as profile cross-sections in almost any shape

- No additional adaptation or conversion measures necessary when changing to another profile shape

High productivity...

Precise and quiet – drive concept

- All axes with servo-electric drives for quiet running, high positioning accuracy

- Short bar changeover times thanks to optimised movement processes and the use of highly dynamic drives

- High energy efficiency thanks to the use of fully electric drives and low-friction linear guides

- Reloading possibility for material bars even during the production process thanks to safe switch-off of critical movements

Short set-up times...

Good accessibility - displacement system

- Fast accessibility to the end of the spindle thanks to longitudinal displacement system integrated in the machine bed

- Small space requirement, since only the upper section of the loading magazine is displaced

- Additional lateral displacement of the loading magazine using a rail system integrated in the machine base available as an option

Short set-up times...

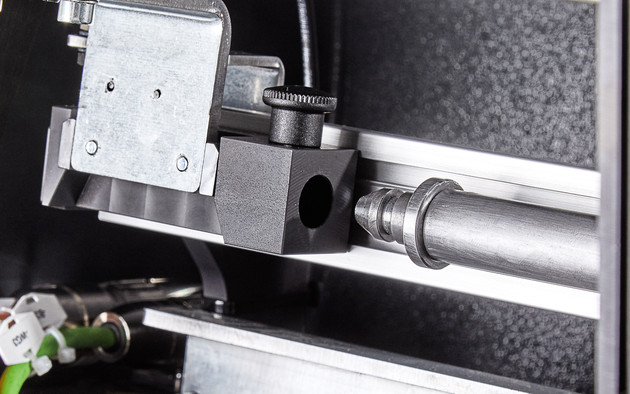

Simple refitting - pusher quick-change system

- Simple replacement of the pusher through the quick-change system

- Good accessibility thanks to wide opening of the machine panelling

- Integrated rack on the machine stand for fast access to the pushers available

Optimum material bar guiding...

Perfectly matched - spindle liners

- Can be delivered for a wide range or lathe types

- Adapt the diameter of the spindle throughput to diameter or profile of the bars

- Reliable pushing into the spindle

- Better guidance in the spindle throughput

In order to adapt the short bar loader to the different general production conditions, the SL 80 V has a modular design, which means there is a choice as follows between various options when ordering the loading magazine in particular for material storage:

The storage system “” represents the classic short loader design and comprises a material storage 560 mm in length with angle adjustment for maximum flexibility.

With the storage system “Cycle belt” the “ramp” is replaced by a chain conveyor with mounted carriers for the material bars. This type of storage for the material bars is especially designed for the precisely positioned feeding of customer-specific profile material which cannot be guided safely via the “ramp” due to its contour.

As an alternative to the long material storage with the “Ramp” system, the storage system “” is also available with a very short material storage as the most compact SL 80 V design. This is intended for applications where only very small series are produced with frequently changing material diameters or profile shapes.

The storage system “” was developed for the ergonomic loading of the SL 80 V, particularly when bar material with a diameter greater than 50 mm is often processed. Here, the material bars are set down on a ramp at a height of approx. 500 to 700 mm independently of the centre axis height of the lathe, from where a lift system automatically feeds the material bar to the upper material storage.