unirobot 3PW pro

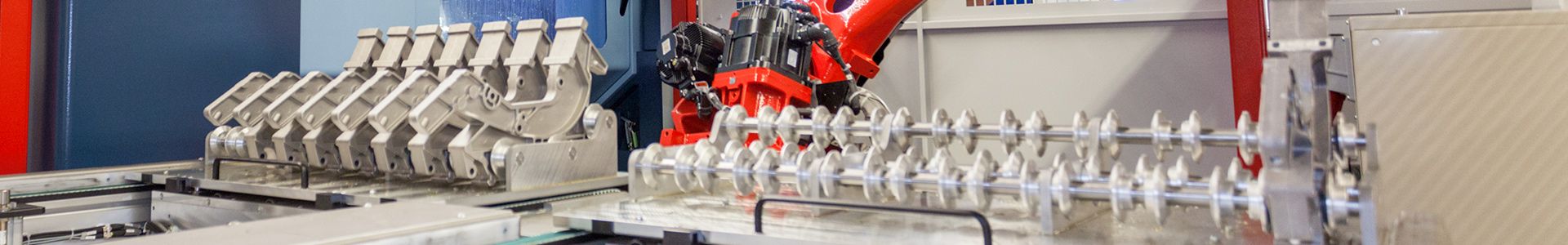

An handling system with 3 trolleys for taking stacked workpiece carriers in formats of up to max. 600 x 400 mm and automated pallet changer.

The Unirobot 3PW pro loading and unloading system is suitable for the automation of CNC-controlled lathes, milling machines, boring centres, presses, cutting dies and many more.

It is fitted with a modern 6-axle industrial robot, which handles the workpieces by means of a gripper system tailored to specific workpiece types.

The robot cell is fitted and anchored to a plinth in front of the loading doors of the machine tool. Access to the machine tool working space for preparations and adjustments is ensured due to sufficient space between the robot and the machine tool. Our Uniprotect safety fence system provides a secure boundary around the working area of the robot. A sliding door gives access to the robot cell.

The feed and removal of the workpieces is by workpiece carriers of a format of max. 600 x 400 mm. The workpiece carriers are fed to and removed from the robot cell by trolleys. The robot cell is equipped with three shafts, one for an unmachined part trolley and one for a finished part trolley.

The workpiece carriers can be stacked on the unmachined part trolley up to a maximum height of 880 mm. The handling of the workpiece carriers is by a pallet changer. The pallet changer takes the workpiece carriers with unmachined parts from the unmachined parts trolley and places them on the working level of the robot for removal of the workpieces and insertion into the machine tool. Once processed, the workpiece carriers with finished parts are stacked on the finished parts trolley.

The operation and programming of all the robot cell functions is via a compact, user-friendly manual programming unit with touch screen.