unirobot P khs

A compact handling system with drawer system for taking 2 to 12 workpiece carriers in formats of up to max. 600 x 400 mm.

The Unirobot P loading and unloading system is suitable for the automation of CNC-controlled lathes, milling machines, boring centres, presses, cutting dies and many more.

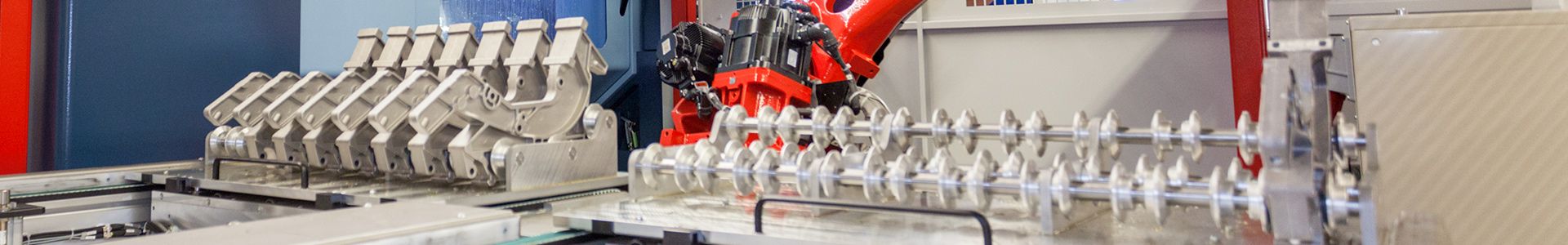

It is fitted with a modern 6-axle industrial robot, which handles the workpieces by means of a gripper system tailored to specific workpiece types.

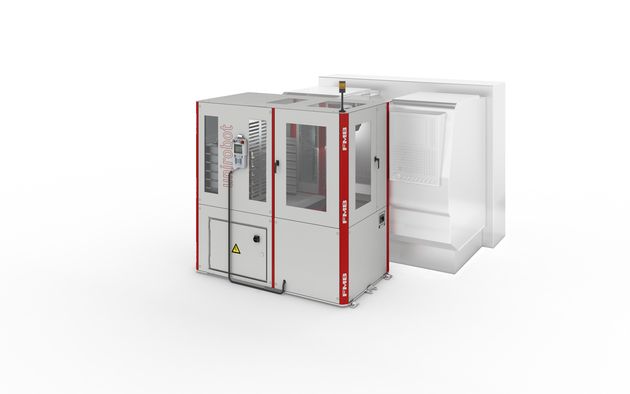

The robot cell is fitted in front of the loading doors of the machine tool. A rail system anchored to the floor enables the robot cell to be moved in relation to the machine tool for fitting and maintenance works. Three zero indexing points on the rail system enable the robot cell to be fixed in a precise location after being pushed back into the working position.

A torsion-resistant steel frame forms the basis for all parts fitted to and incorporated in the robot cell. The robot cell is equipped with an all-round protective cladding. Access to the robot cell can be gained via three maintenance doors and a loading/unloading door.

The feed and removal of the workpieces is by workpiece carriers of a format of max. 600 x 400 mm. The workpiece carriers are delivered on pneumatically-driven drawers to the robot for removal of the workpieces and insertion into the machine tool.

Depending on the workpiece height, the robot cell can be configured with 2 to 5 drawers in a S-Version, with 4 to 7 drawers in a L-Version and with 6 to 12 drawers in a XL-Version.

The robot cell may be fitted with an optional divider to separate the loading space from the working space of the robot, thus enabling the workpiece carrier to be loaded and unloaded during a work process.

The robot control unit is built into the frame, so that the whole unit only requires a space of 1,800 x 900 mm (S-Version), 2.000 x 1100 mm (L-Version) and 2.557 x 1800 mm (XL-Version) plus 1,000 mm room for manoeuvre.

The operation and programming of all the robot cell functions is via a compact, user-friendly manual programming unit with touch screen.