unirobot PORTAL P

A compact automation cell in the form of an overhead installation above a lathe, with drawer system for taking 2, 3, 4 or 5 workpiece carriers in formats of up to max. 600 x 400 mm.

Instructions:

Development of a loading and unloading system for a lathe, which saves space and does not restrict the access to the working space.

Implementation:

The formulation of a concept in which an overhead automation cell is installed above the lathe, with the robot mounted on a horizontal track. The drawer system for holding the workpiece carriers is arranged above the chip conveyor.

Description:

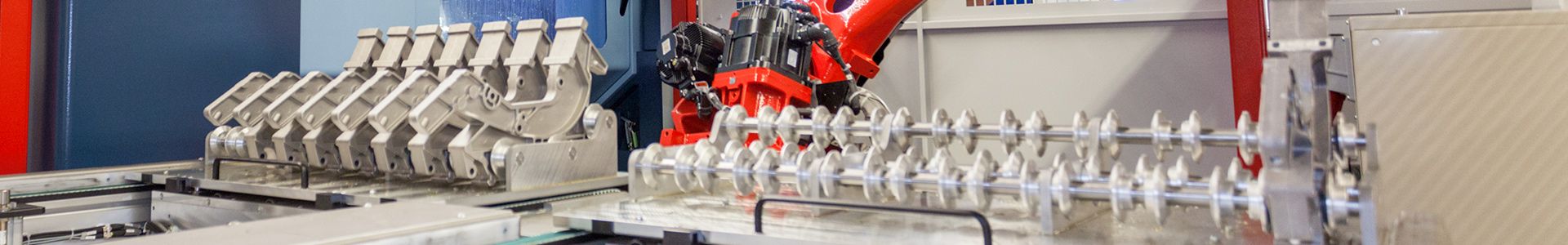

The Unirobot PORTAL P loading and unloading system is designed especially for the space-saving automation of certain types of machine tool. Implemented in conjunction with the Miyano BNA-42S and Hardinge GT27 lathes, It is fitted with a modern, horizontally traversing 6-axle industrial robot, which handles the workpieces by means of a gripper system tailored to specific workpiece types. The robot cell is fitted above the machine tool, keeping the space needed to a minimum.

A torsion-resistant steel frame forms the basis for all parts fitted to and incorporated in the robot cell. The robot cell is equipped with a protective cladding. Two or three maintenance doors give access to the robot cell or machine tool.

The feed and removal of the workpieces is by workpiece carriers of a format of max. 600 x 400 mm. The workpiece carriers are delivered on pneumatically-driven drawers to the robot for removal of the workpieces and insertion into the machine tool. Depending on the workpiece height, the robot cell can be configured with 2 to 5 drawers (PORTAL 2P, PORTAL 3P, PORTAL 4P or PORTAL 5P).

The overhead mounting above the lathe means that the additional space required for handling is only 0.75 m².

The operation and programming of all the robot cell functions is via a compact, user-friendly manual programming unit with touch screen.