MT51 BF

A rear loader for round, square and hexagonal section materials of between 10 and 51 mm diameter.

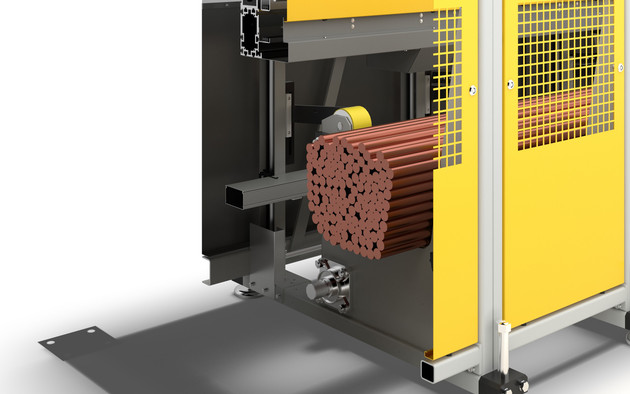

The FMB MT51 BF is a rear loader designed for the processing of round, square and hexagonal section materials of diameters ranging from 10 to 51 mm. Depending on the variant, the maximum material bar length is 3,300 or 4,200 mm. The bars are stored on a bundle loader integrated in the machine frame.

After transfer to the guide channel by the bar lift, the material bar is fed by the feed system to the guide tubes arranged in a drum. During processing the material bar does not come into contact with the loading magazine.

In order to ensure optimum vibration-free guidance of the bar, it is necessary to insert spindle liners to match the diameter. The MT51 BF operates on the principle of a two-stage feed. The swivelling pusher means that a very compact, space-saving construction can be achieved.

Area of application:

Multi-spindle lathes up to 51 mm nominal throughput, on which the material is fed into the guide tubes from behind.

Features

- Short design based on a two-stage feed principle (swivelling pusher)

- Torsion-resistant frame construction to accommodate the maximum possible insertion forces

- Simple changing of the inserts for efficient adaptation of the guide channel to different material diameters

- Integrated bundle loader with a loading capacity of 2.5 t

Ergonomic and simple operation...

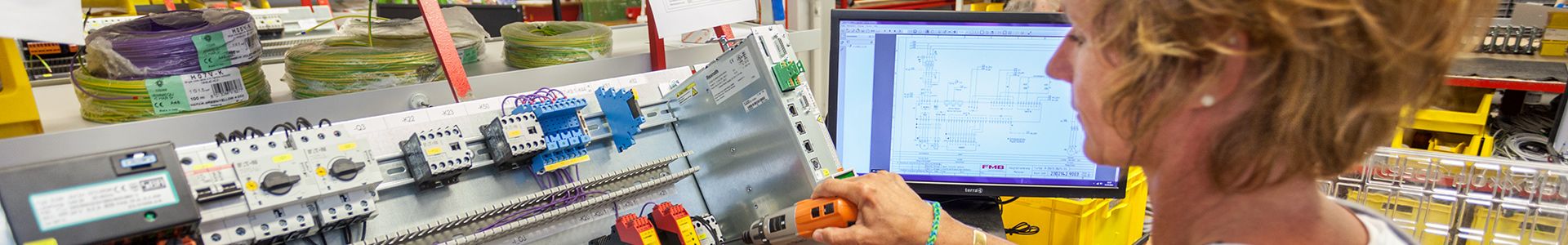

Mobile control panel

Easy handling of the FMB loading magazine is supported by a detachable user-friendly control panel. It can be combined with a high-performance programmable logic control (PLC) system to enable FMB to produce very flexible customer-specific special functions and processes.

Efficient, practical handling...

Bar loading

The space-saving bundle loader integrated in the loading magazine has a loading capacity of 2.5 t, in order to allow the lathe to operate for a maximum length of machining time without interruption. This design also allows for very efficient loading of large material quantities.

Efficient, practical handling...

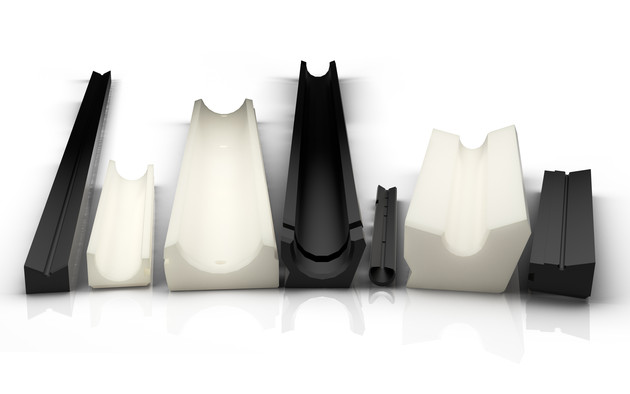

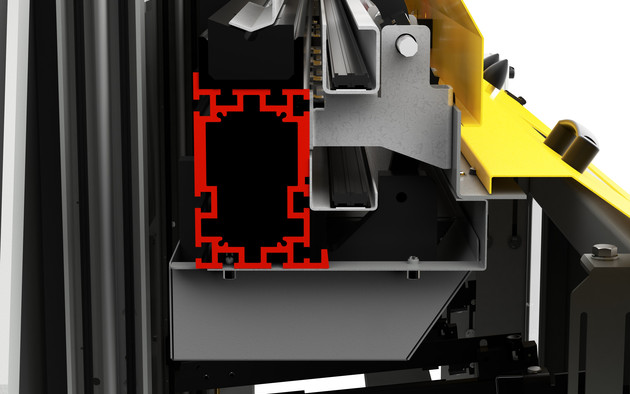

Guide channel inserts

The polyamide guide channel inserts with sound damping properties are easy to replace so that the channel diameter can be adapted to the optimum diameter range of the material bars to be processed. Each guide channel can also be combined with others with different pusher diameters.

Efficient, practical handling...

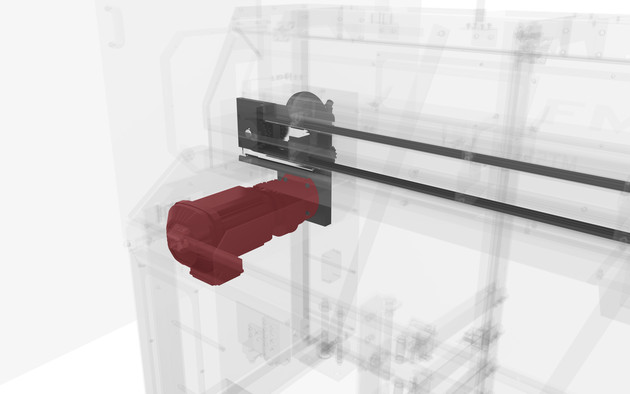

Insertion forces

The insertion forces of the pusher are infinitely adjustable, with reference to a waypoint on the control panel. The generously dimensioned drive motor enables maximum insertion forces to be generated for the secure feed of the material bar into the feed grippers.

Stable design...

Machine support

The solid, torsion-resistant machine support forms the solid basis for the loading magazine, enabling the maximum possible insertion forces to be received.

Stable design...

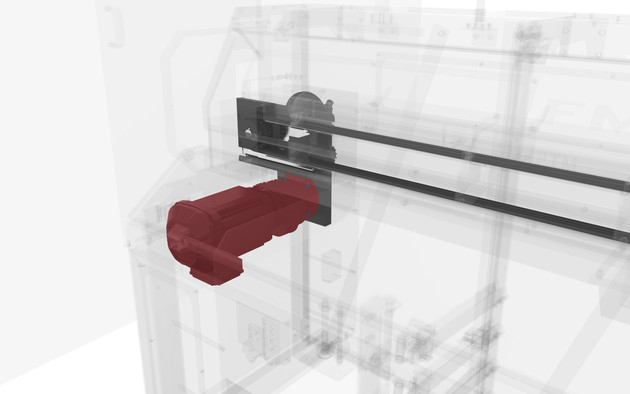

Drive design

The very robust, low-maintenance chain drive means reliable running of the pusher when inserting the material bars.

Optimum material bar guidance...

Spindle liners

To enable the spindle opening to be optimally adapted to match the guide channel diameter, the appropriate spindle liners are usually obtained from the manufacturer of the multi-spindle lathe.

Optimum material bar guidance...

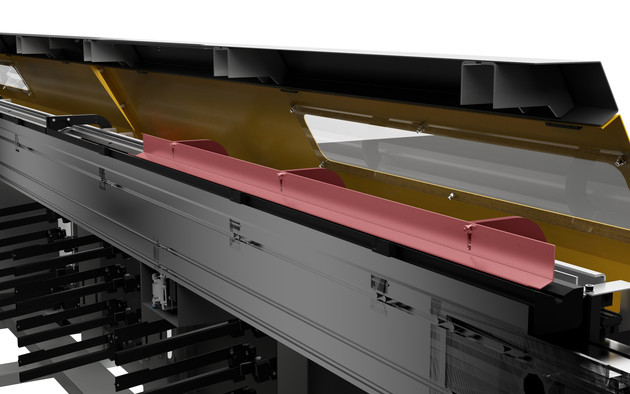

Hold-down device

The hold-down system allows for high insertion forces of the material bars in the feed grippers. Thin material bars are prevented from slipping out.