turbo 20-100

Magazine for bar diameters of 20–100 mm.

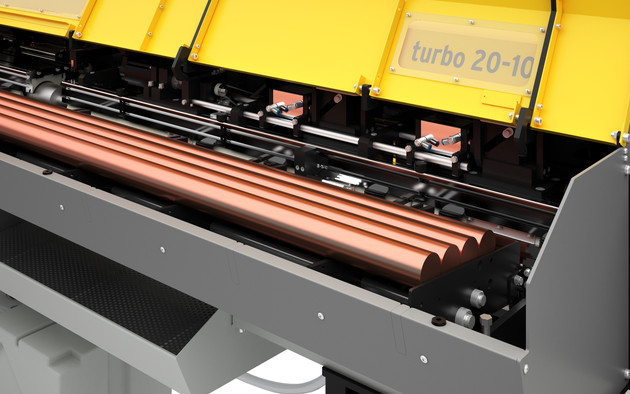

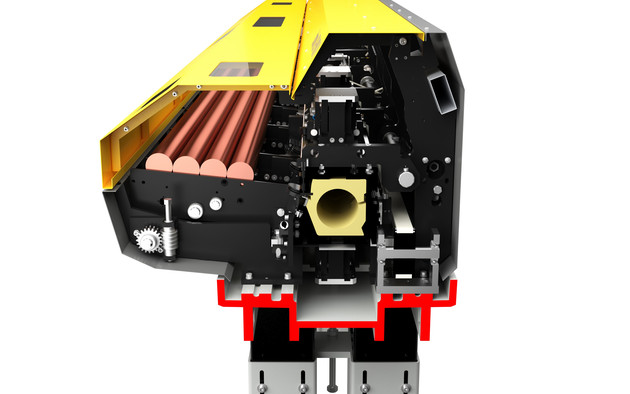

The FMB turbo 20-100 is the loading magazine that currently has the greatest available number of guide channels. It is designed for a diameter range of 20–100 mm and works on the principle of a two-stage feed. The swivelling pusher means that a very compact, space-saving construction can be achieved. The solid machine bed of grey cast iron also ensures the necessary stability, especially for the precise machining of larger material bar diameters.

Area of application:

Single-spindle lathes with up to 100 mm nominal throughput gap, intended for the permanent processing of medium-sized to very large diameter ranges or the occasional processing of smaller bar diameters.

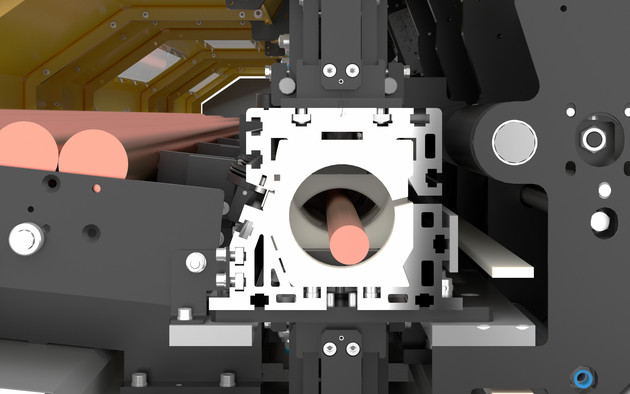

Where lathes are used for material bars with frequently differing diameters, the turbo 20-100 V variant model provides an optimum solution for further production efficiency increases. The V variant has moveable guiding segments that are automatically set to the required material bar diameter, thus preventing the need for refitting the guide channel inserts or changing the pusher over wide ranges.

The proven benefits of the hydrodynamic bearing effect of the oil-flushed channel are not affected. After inputting the material bar diameter on the control panel, the guiding segments in the channel set themselves and the stops of the material bar separation system are automatically moved to the required position.

Features

- Short design based on a two-stage feed principle (swivelling pusher)

- Fast, simple changing of the inserts for efficient adaptation of the guide channel to different material diameters

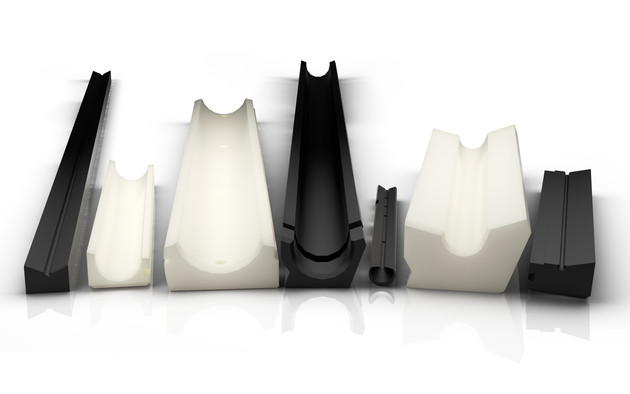

- Highest possible guide quality and vibration damping by the use of polyurethane inserts, combined with a solid machine bed of grey cast iron.

- Optional V variant with automatic diameter adjustment of the guiding segments in the channel and material bar separation by means of inputs on the control panel.

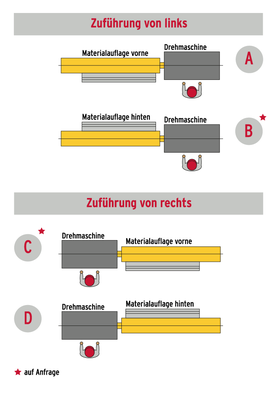

Available installation situations

Ergonomic and simple operation...

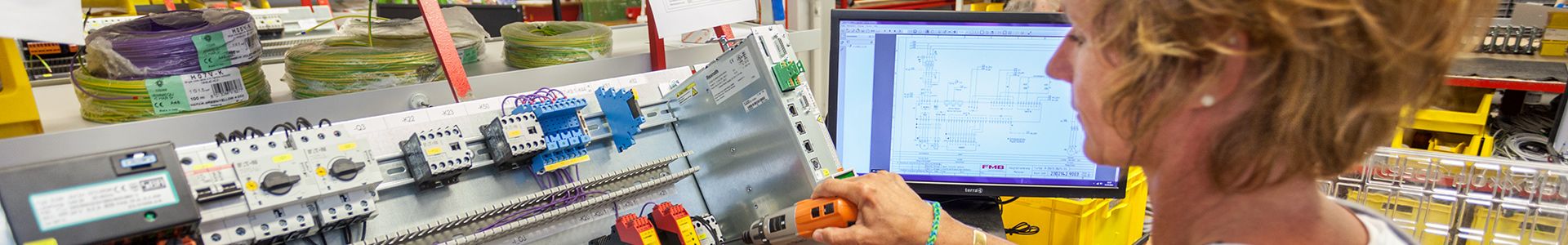

Mobile control panel

Easy handling of the FMB loading magazine is supported by a detachable user-friendly control panel. It can be combined with a high-performance programmable logic control (PLC) system to enable FMB to produce very flexible customer-specific special functions and processes.

Ergonomic and simple operation...

Bar loading

The wide material storage facility offers space for 2 to 12 bars, depending on diameter, in order to allow the lathe to operate for a maximum length of machining time without interruption. The inclination angle of the material storage facility can be infinitely adjusted so that it always guarantees the best possible feed of all kinds of material and profile.

Efficient, practical handling...

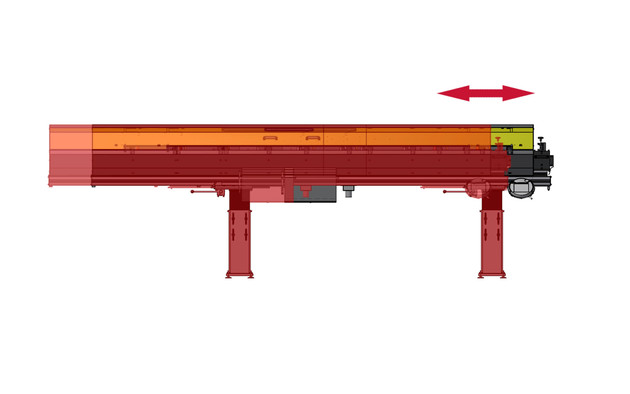

Installation position

The optional shifting device makes it possible to move the loading magazine up to 400 mm away from the lathe. This practical feature increases accessibility to the lathe for service technicians, e.g. when replacing spindle liners, or, when switching variable lathes from short-turning to long-turning mode, ensures the shortest distance between loading magazine and spindle stock at all times.

Efficient, practical handling...

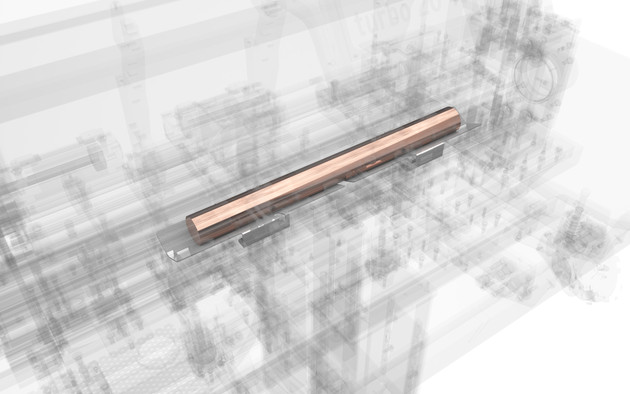

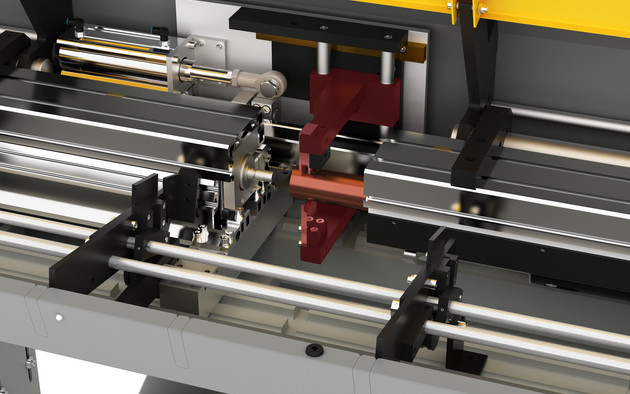

Guide channel inserts

The polyurethane guide channel inserts with sound damping properties are quick and easy to replace, so that the channel diameter can be adapted to the optimum diameter range of the material bars to be processed.

Efficient, practical handling...

Adjustable guide channel (V variant)

The moveable guiding segments are automatically set to the required material bar diameter. This prevents the need for changing the guide channel inserts and the pusher over a wide range of diameters*.

* When processing diameters < 30 mm, it is recommended that the adjustment of the guide channel diameter is checked by FMB

Efficient, practical handling...

Automatically adjustable material separation (V variants)

The stops for the material bar separation on the lateral material storage facility automatically move to the preset material bar diameter.

Efficient, practical handling...

Put down device

The put down device integrated into the guide channel ensures gentle changing of the material bars, especially those with large diameters.

Efficient, practical handling...

Short loading function (V variants)

When using spindle reduction liners, the optional short loading function enables material bars with a length of 850 to 1,250 mm to be loaded with direct guidance into the spindle of the lathe. This enables large-diameter material bars to be processed at very high rotation speeds with maximum precision.

Stable design...

Machine support

The solid, torsion-resistant machine bed of grey cast iron forms the solid basis for the loading magazine. This guarantees the highest possible guide quality and vibration damping.

Stable design...

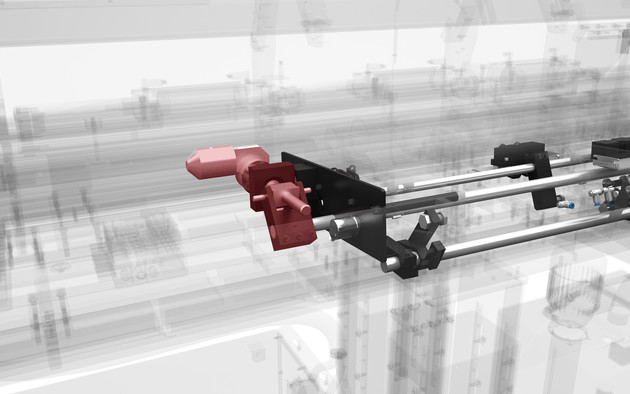

Material bar grippers

The stable gripper design guarantees secure drawing in of the material bar and removal of the remnant piece.

Optimum material bar guidance...

Spindle liners

On request FMB can also supply spindle liners to match a substantial number of lathe types; these enable the spindle opening to be optimally adapted to match the guide channel diameter.

Optimum material bar guidance...

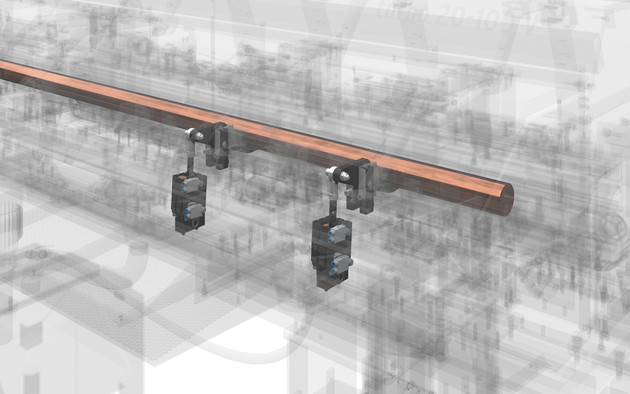

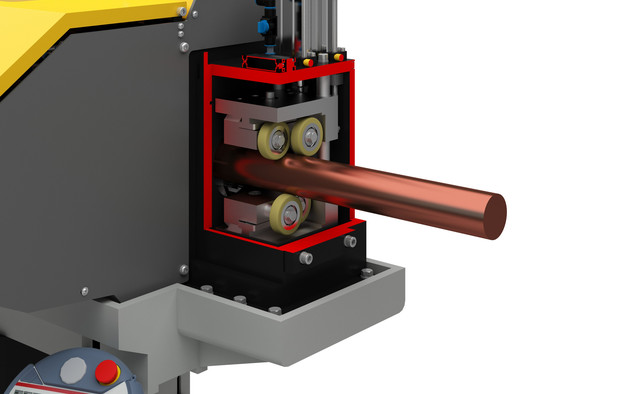

Steady

The steady at the end of the guide channel takes the form of a flexible roller steady for the processing of round material bars. When processing round, square and hexagonal section materials the guide rollers can be replaced by appropriate material guides (guide jaws). This enables the steady to be set to the dimensions of the material bar, thus guaranteeing optimum guidance even of small-diameter bars in a larger guide channel.