turbo 2-20

The smallest model in the FMB turbo series.

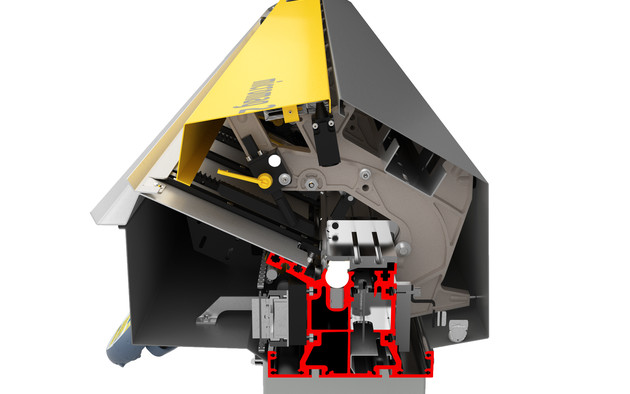

It is a magazine for bar diameters from 2–23 mm and works on the principle of two-stage feed. The swivelling pusher means that a very compact, space-saving construction can be achieved.

Area of application:

Sliding headstock lathes with up to 23 mm nominal throughput gap, which process small diameter ranges.

Designed especially for the processing, the turbo 2-20 P variant model offers an attractive alternative for the optimum separation of the material bars. The lateral material storage of the P variant is also fitted with swivelling pilgrim step separation to enable the material bar to be securely transferred into the guide channel.

- Short design based on a two-stage feed principle (swivelling pusher)

- Loading of the material storage facility is possible with the hood closed, thus avoiding the need to interrupt the process.

- Fast, simple changing of the inserts for efficient adaptation of the guide channel to different material diameters

- Optional P variant with pilgrim step separation for the optimum separation of very small material bar diameters

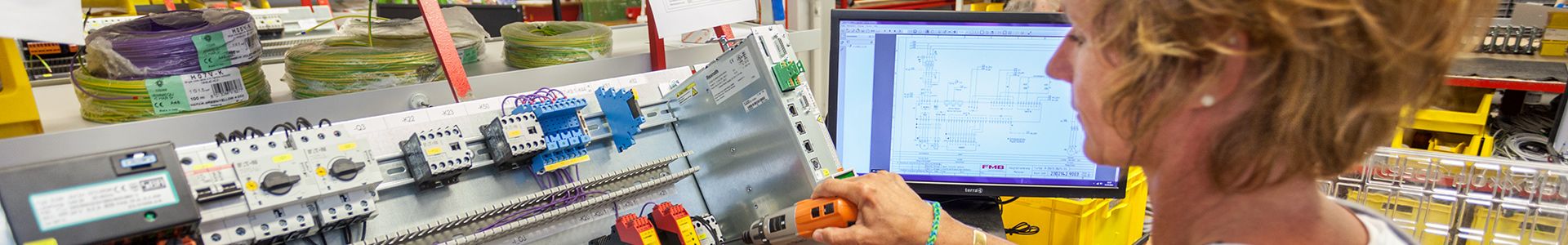

Modern touch control with generously sized 8.4“ screen makes an intuitive operating concept

possible for a faster learning phase. Integrated assistant function for guided set up for inexperienced users.

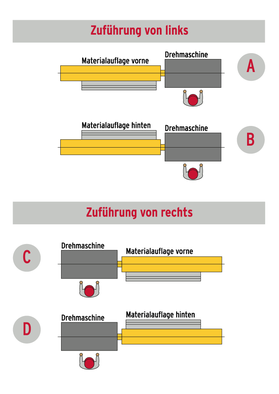

Available installation situations

Efficient, practical handling...

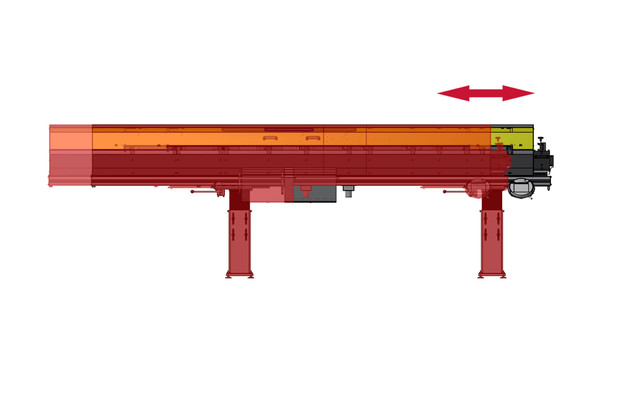

Installation position

The optional shifting device makes it possible to move the loading magazine up to 400 mm away from the lathe. This practical feature increases accessibility to the lathe for service technicians, e.g. when replacing spindle liners, or, when switching variable lathes from short-turning to long-turning mode, ensures the shortest distance between loading magazine and spindle stock at all times.

Efficient, practical handling...

Bar loading

The side opening in the machine panelling enables the material storage to be loaded with the hood closed, thus avoiding the need to interrupt the process. It has capacity for 8 to 100 bars, depending on the diameter

Efficient, practical handling...

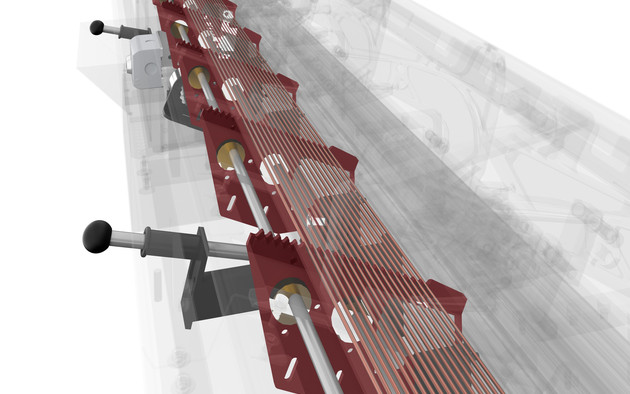

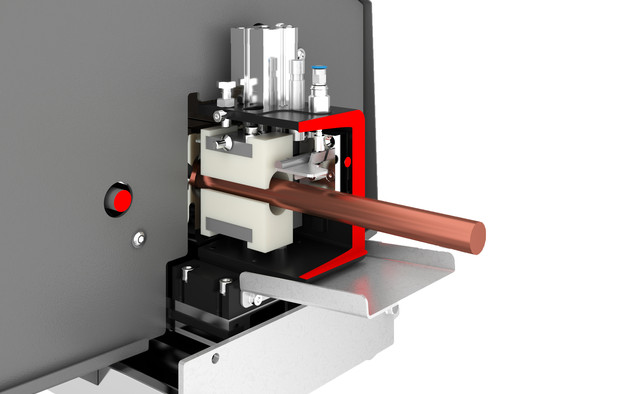

Bar separation (P variant)

The pilgrim step separation device installed beneath the material storage facility can be swivelled upwards readily for processing bars with diameters < 4 mm, thus ensuring optimum separation.

Stable design...

Machine support

The torsion-resistant machine support of extruded aluminium forms the solid basis for the loading magazine. It also holds the diameter-related inserts for the guide channel.

Stable design...

Machine support

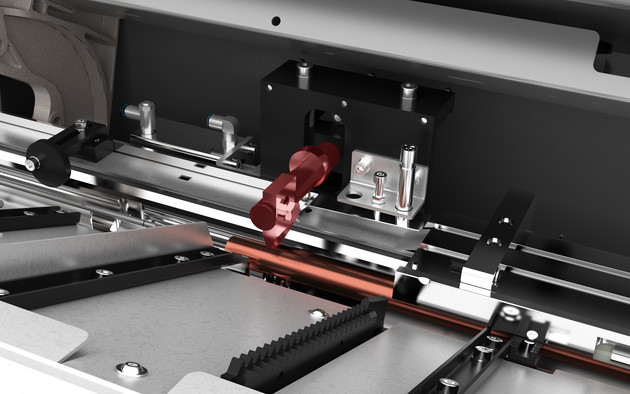

The stable gripper design guarantees secure drawing in of the material bar and removal of the remnant piece.

Optimum material bar guidance...

Spindle liners

On request FMB can also supply spindle liners to match a substantial number of lathe types; these enable the spindle opening to be optimally adapted to match the guide channel diameter.

Optimum material bar guidance...

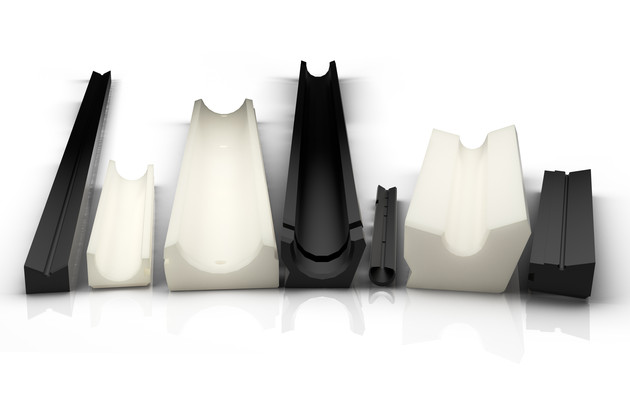

Steady

The steady at the end of the guide channel is adjustable and designed with jaws, enabling it to be used for round, square or hexagonal section materials. The steady has easily replaceable (material guides), enabling it to be set to the dimensions of the material bar, thus guaranteeing optimum guidance even of small-diameter bars in a larger guide channel.

Optimum material bar guidance...

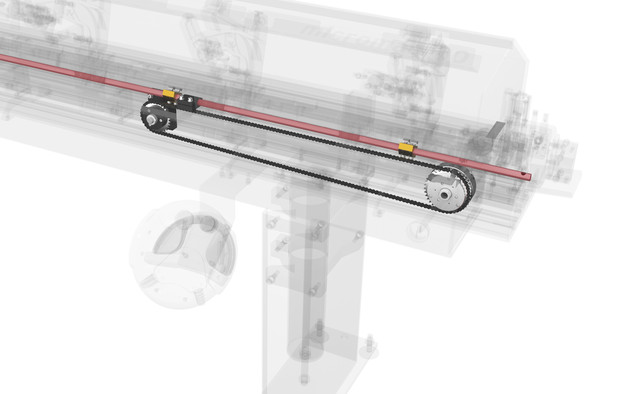

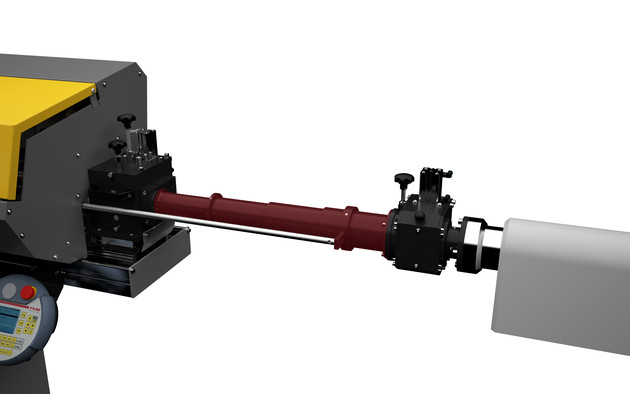

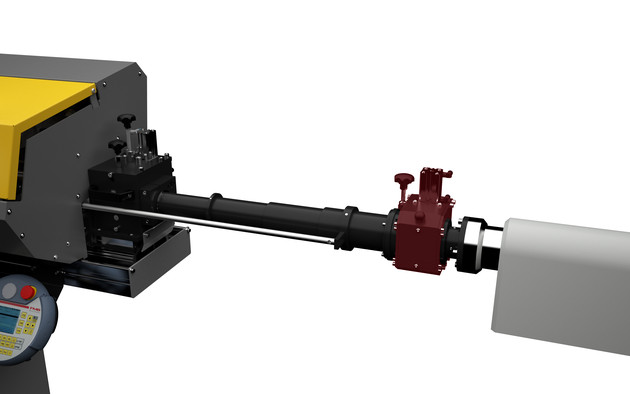

Synchronizing device

When using a moving spindle stock (e.g. in sliding headstock mode), the synchronizing device uses a coupling system to couple the bar feed device of the loading magazine mechanically to the spindle stock, thus ensuring synchronisation with the movement of the pusher. As an option, the position during this movement can also be monitored by a sensor to prevent any possible collisions, e.g. when switching from fixed headstock to sliding headstock mode.

Optimum material bar guidance...

Telescopic tubes

Telescopic tubes are used to bridge the gap when fitting a bar loading magazine to a lathe with a sliding spindle stock. FMB offers an optional package to suit each type of lathe, to ensure secure protection of the rotating bar and the best possible guidance.

Optimum material bar guidance...

Spindle stock steady

In addition to the use of a telescopic tube, FMB offers a moving steady for lathes with large travel distances along the Z axis and long spindles. This is linked to the spindle stock, thus offering an additional support point for the material bar in order to reduce the free length between the steady and the collet in the lathe. It reduces vibrations in the material bar and has a positive effect on the production quality of the parts.