kontur 70

Specially designed for processing profiled material bars.

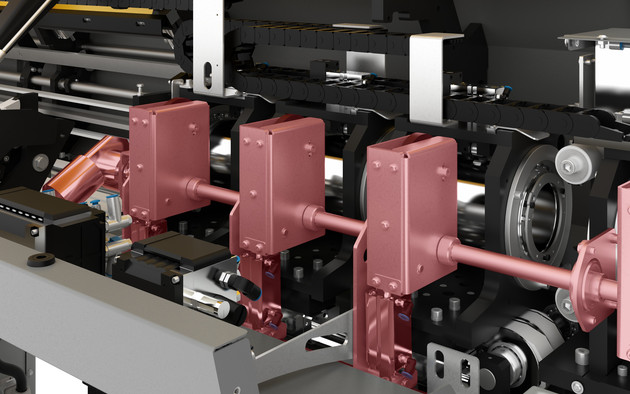

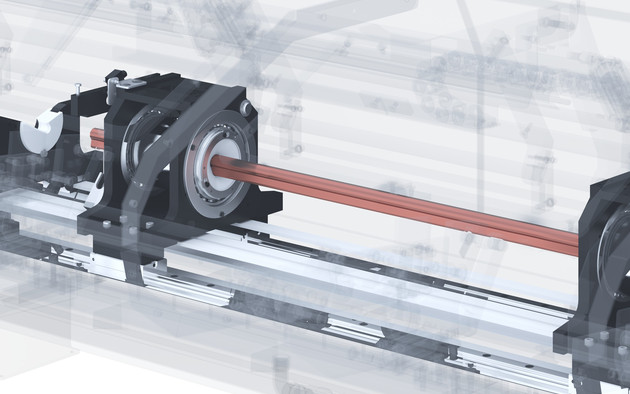

Bar loading magazines with ball-bearing mounted bar guidance are fundamentally different from solutions with hydrodynamic guidance. Whenever profiled material bars need to be fed to the lathe in reproducible alignment, FMB uses ball bearing-mounted bushes as the guiding element. In these cases, too, the material bars can be longer than the spindle length of the lathe, so that in addition to the staged feed of the material bars, the loading magazine also guides the rotating bars outside the lathe. In order to provide optimum guidance even for asymmetrically profiled cross-sections, FMB uses guide bushes with a locating hole that corresponds to the profile of the material bar. This concept includes an alignment device developed and patented by FMB, which inserts the material bars at a precise, repeatable angle into the clamping system of the lathe.

This system is generally suitable for bars with individual, hexagonal or quadratic exterior contours in full cross-section. FMB currently offers the Kontur 70, a magazine for bars up to 3.2 m in length and an external diameter of between 20 and 70 mm. The bar materials used are generally steels, aluminium and brass.

This system has been designed for use with short-turning single spindle lathes. Particularly when processing profiled material bars in a wide variety of forms, lathes can be optimally automated with a bushing-aligned bar loading magazine from FMB.

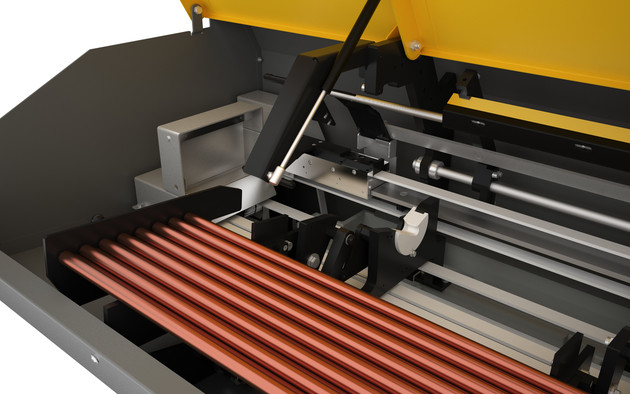

The FMB kontur 70 is a loading magazine specially designed for processing profiled material bars. The material bars are guided by bushing units on ball bearings. These are fitted with at least 8 replaceable plastic guide bushes, which have locating holes corresponding to the profile of the material bar. It is designed for materials bars with external diameters between 20 and 70 mm, and works on the principle of a two-stage feed.

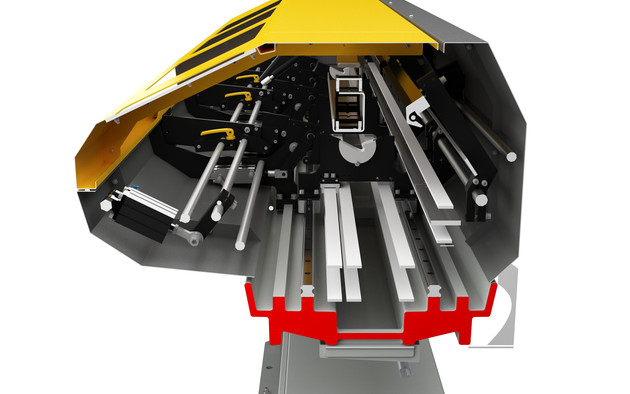

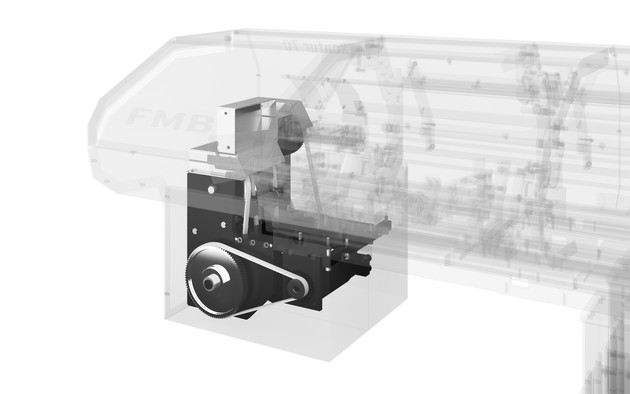

The swivelling pusher means that a very compact, space-saving construction can be achieved. The solid machine bed of grey cast iron also ensures the necessary stability, especially for the precise machining of asymmetrical profile types.

Area of application:

Single-spindle lathes up to approx. 70 mm nominal throughput, on which profiles material bars of lengths up to 3,200 mm are continuously machined.

Features

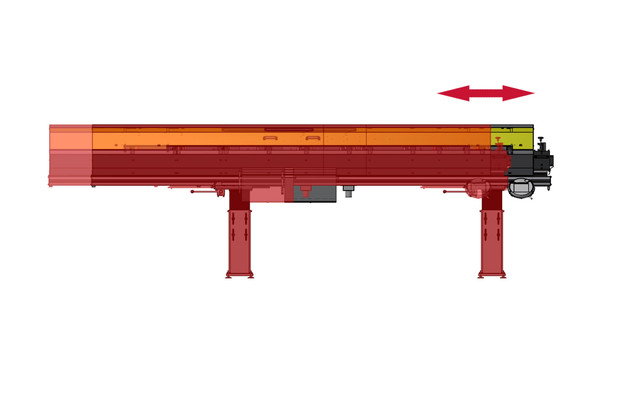

- Short design based on a two-stage feed principle (swivelling pusher)

- Fast, simple changing of the guide bushes for efficient adaptation to different profile types

- The best possible guidance quality from bushing units in linear formation on ball bearings

- Patented alignment unit for the bushes for precisely angled material feed

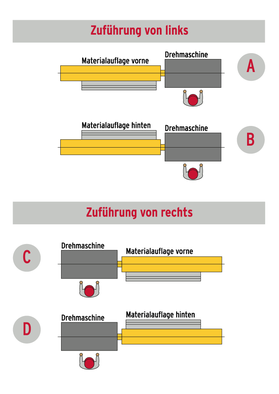

Available installation situations

Ergonomic and simple operation...

Mobile control panel

Easy handling of the FMB loading magazine is supported by a detachable user-friendly control panel. It can be combined with a high-performance programmable logic control (PLC) system to enable FMB to produce very flexible customer-specific special functions and processes.

Efficient, practical handling...

Bar loading

The wide material storage facility offers space for 3 to 13 bars, depending on diameter, in order to allow the lathe to operate for a maximum length of machining time without interruption. The inclination angle of the material storage facility can be infinitely adjusted so that it always guarantees the best possible feed of all kinds of material and profile.

Efficient, practical handling...

Installation position

The optional shifting device makes it possible to move the loading magazine up to 400 mm away from the lathe. This practical feature increases accessibility to the lathe for service technicians, e.g. when replacing spindle liners, or, when switching variable lathes from short-turning to long-turning mode, ensures the shortest distance between loading magazine and spindle stock at all times.

Efficient, practical handling...

Guide bushes

The guide bushes can be replaced quickly and easily, in order to change the loading magazine as required for material bars with a different cross-section or a new profile type.

Efficient, practical handling...

Alignment unit

The Kontur 70 may optionally be fitted with a patented alignment unit to adjust the bushes during the eccentric machining of regular and irregular profiles to the correct feed position for the material bars. This enables a precise positioning when feeding material bars, including into profiled collets.

Stable design...

Machine support

The solid, torsion-resistant machine bed of grey cast iron forms the solid basis for the loading magazine. This guarantees the highest possible guide quality and vibration damping.

Stable design...

Drive design

The very robust yet high-precision toothed belt drive with servo motors means precise control and low-noise running when moving the bushing units and pusher.

Optimum material bar guidance...

Spindle liners

On request FMB can also supply spindle liners to match a substantial number of lathe types; these enable the spindle opening to be optimally adapted to match the guide channel diameter.

Optimum material bar guidance...

Bush guidance

The close-fitting guide bushes, tailored individually to the material bars, are arranged on ball bearings within the bushing unit to ensure precise running. In conjunction with the smooth-running bushing units mounted on linear guides, they guide the material bars with great accuracy.