LSK 38

Designed for lathes with a large Z-axis movement

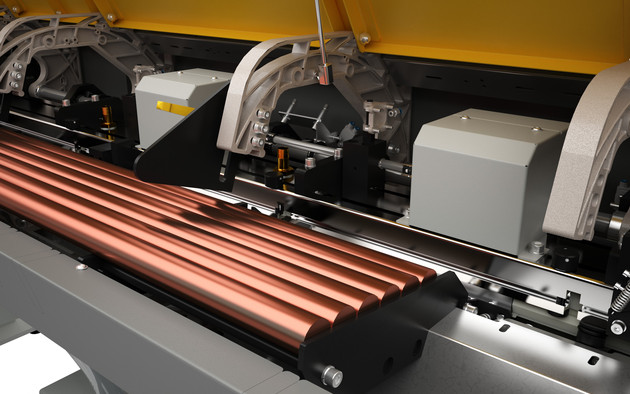

The LSK 38 is a loading magazine for bar diameters of 5–38 mm, specially developed for lathes with a spindle stock that moves along the Z-axis causing substantial differences in the distance between the loading magazine and the lathe chuck. The feeding of the material bars between the loading magazine and spindle has a crucial effect on the smooth running and thus the overall quality of the lathe process. This means that large unguided areas, which especially in sliding headstock lathe processes can change substantially during and beyond the machining process, should be avoided wherever possible.

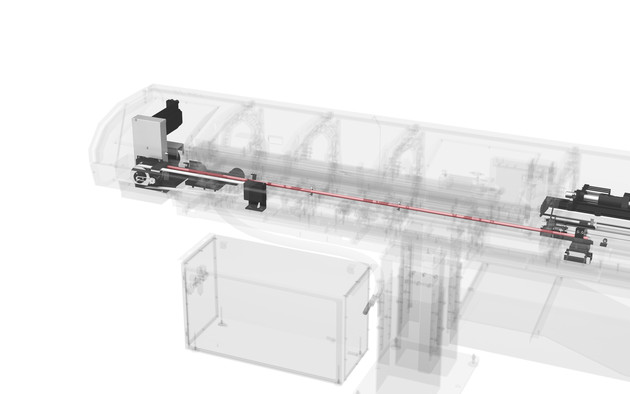

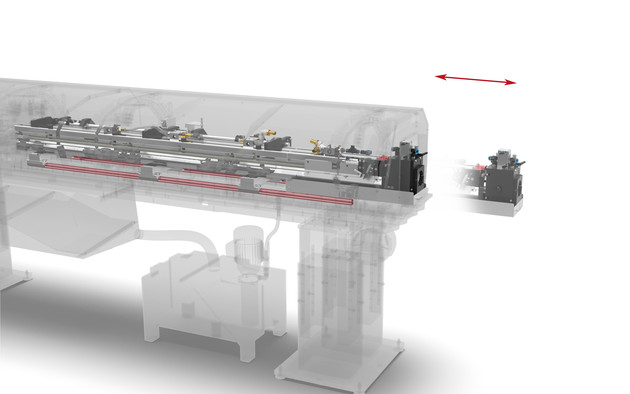

An optimum solution is offered by FMB’s patented concept of the moving guide channel. The whole guide channel is movable as it is mounted on linear tracks and coupled with the end of the lathe spindle.

This means that the guide channel follows every movement of the spindle stock, which means there is no longer an unguided area of the material bar between the loading magazine and lathe at any time. The result is a notably more efficient lathe process while maintaining the quality of the part. The LSK 38 also operates on the principle of a two-stage feed. The swivelling pusher means that a very compact, space-saving construction can be achieved. The solid machine bed of grey cast iron also ensures the necessary stability, especially for the precise machining of larger material bar diameters.

Area of application:

Single-spindle lathes up to 38 mm nominal throughput, which are equipped with a spindle stock that moves along the Z-axis. The use of the LSK 38 requires the approval by the lathe manufacturer.

Merkmale

- Moveable guide channel guarantees constant operating conditions by ensuring an unchanged gap between the loading magazine and lathe end.

- Short design based on a two-stage feed principle (swivelling pusher)

- Fast, simple changing of the inserts for efficient adaptation of the guide channel to different material diameters

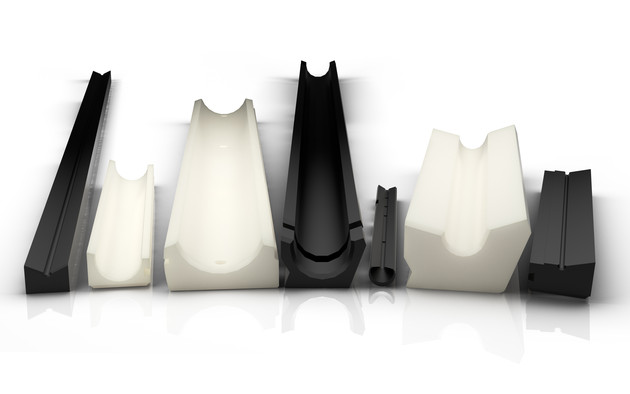

- Highest possible guide quality and vibration damping by the use of polyurethane inserts, combined with a solid machine bed of grey cast iron.

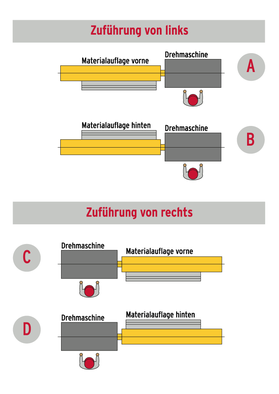

Available installation situations

Ergonomic and simple operation...

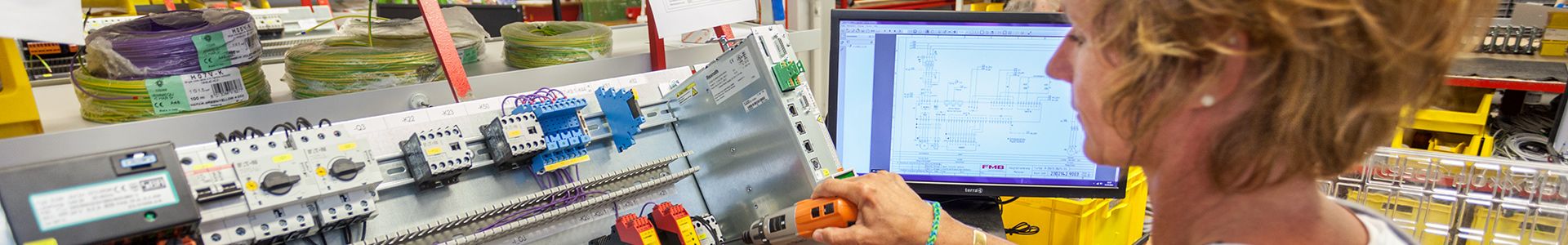

Mobile control panel

Easy handling of the FMB loading magazine is supported by a detachable user-friendly control panel. It can be combined with a high-performance programmable logic control (PLC) system to enable FMB to produce very flexible customer-specific special functions and processes.

Efficient, practical handling...

Bar loading

The wide material storage facility offers space for 6 to 48 bars, depending on diameter, in order to allow the lathe to operate for a maximum length of machining time without interruption. The inclination angle of the material storage facility can be infinitely adjusted so that it always guarantees the best possible feed of all kinds of material and profile.

Efficient, practical handling...

Guide channel inserts

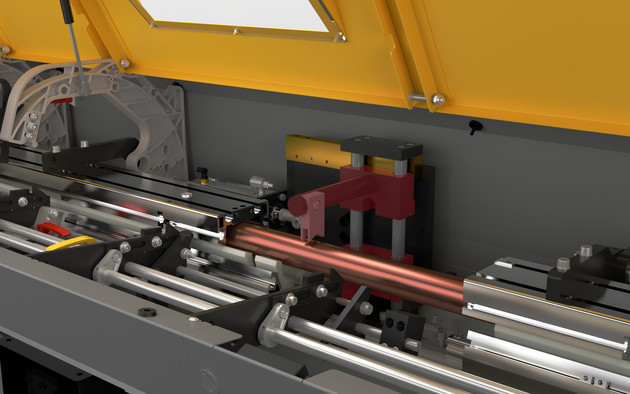

The guide channel inserts are quick easy to replace so that the channel diameter can be adapted to the optimum diameter range of the material bars to be processed.

Stable design...

Machine support

The solid, torsion-resistant machine bed of grey cast iron forms the solid basis for the loading magazine. This guarantees the highest possible guide quality and vibration damping.

Stable design...

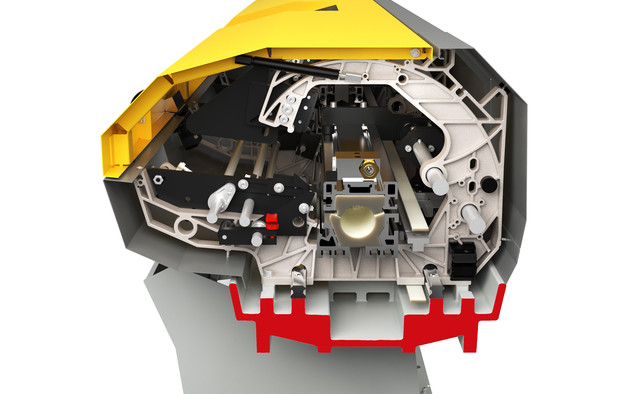

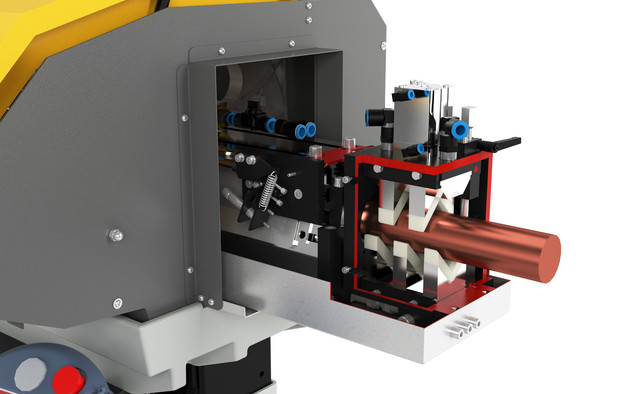

Material bar grippers

The stable gripper design guarantees secure drawing in of the material bar and removal of the remnant piece.

Optimum material bar guidance...

Spindle liners

On request FMB can also supply spindle liners to match a substantial number of lathe types; these enable the spindle opening to be optimally adapted to match the guide channel diameter.

Optimum material bar guidance...

Steady

The steady at the end of the guide channel takes the form of a tapered steady for the processing of round material bars. When processing round, square and hexagonal section materials the tapers can be replaced by appropriate guide jaws. This enables the steady to be set to the dimensions of the material bar, thus guaranteeing optimum guidance even of small-diameter bars in a larger guide channel.

Optimum material bar guidance...

Synchronizing device

When using a moving spindle stock (e.g. in sliding headstock mode), the synchronizing device uses a coupling system to couple the bar feed device of the loading magazine mechanically to the moving guide channel, thus ensuring synchronisation with the movement of the pusher. During this movement, the position is monitored by a sensor to prevent any possible collisions, e.g. when switching from fixed headstock to sliding headstock mode.

Optimum material bar guidance...

Moving guide channel

The moveable guide channel, which is coupled to the spindle stock, guarantees optimum guidance and constant operating conditions by ensuring an unchanged gap between the loading magazine and lathe end. When switching from fixed to sliding headstock mode, it also prevents the need for a change of loading magazine position by means of the shifting device.